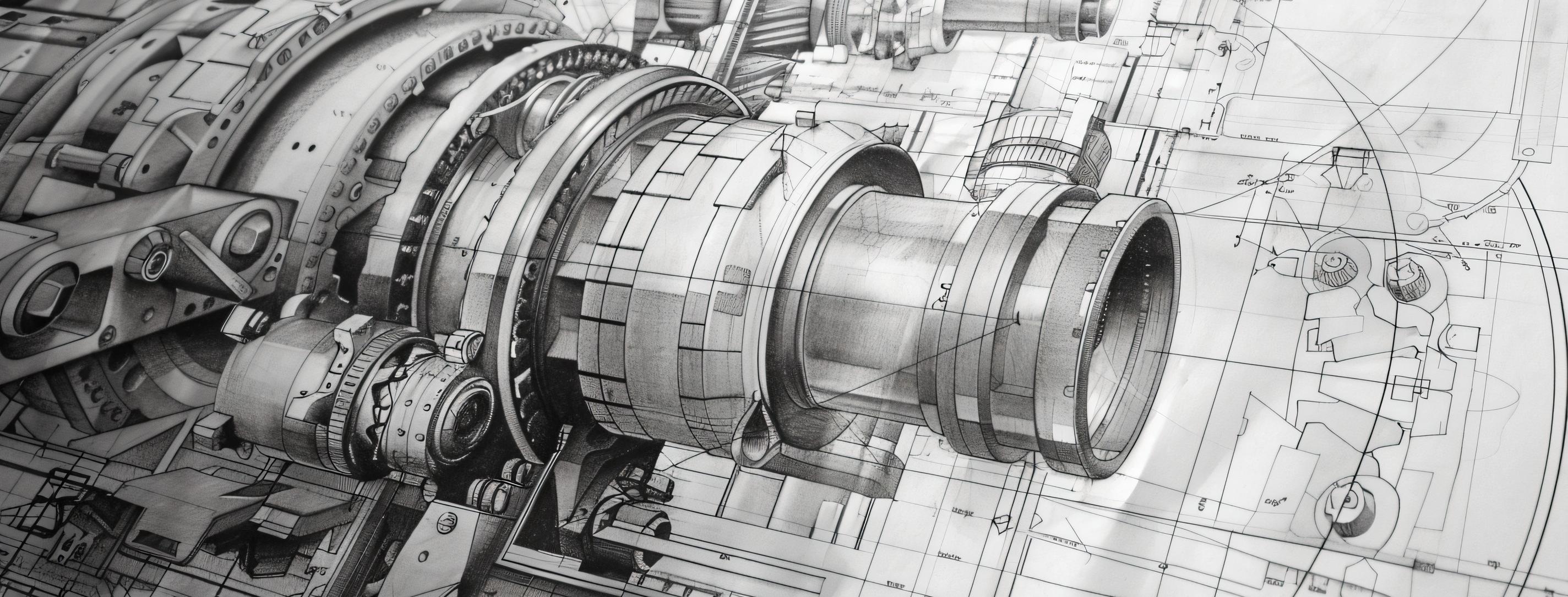

The Durability and Longevity of the HP500 Multi-Cylinder Hydraulic Cone Crusher’s Main Frame

The HP500 Multi-Cylinder Hydraulic Cone Crusher is a cornerstone of modern aggregate and mining operations, renowned for its efficiency and reliability. Central to HP500 Multi-Cylinder Hydraulic Cone Crusher's performance is the main frame, a component engineered to endure extreme operational stresses while maintaining structural integrity for decades. This essay explores the design, material, and manufacturing innovations that enable the HP500 Multi-Cylinder Hydraulic Cone Crusher’s main frame to achieve a service life of 10 to 20 years.

Robust Material Selection

The main frame is constructed from high-grade cast steel, alloyed with elements like chromium and molybdenum to enhance tensile strength and fatigue resistance. The main frame's material undergoes rigorous heat treatment processes, such as quenching and tempering, to optimize hardness and toughness. Such metallurgical excellence ensures the frame resists deformation, even under repetitive high-impact loads from crushing hard rocks like granite or basalt.

Advanced Structural Design

Engineered using finite element analysis (FEA), the main frame’s geometry distributes mechanical stress uniformly, minimizing concentrated fatigue points. The main frame's rib-reinforced architecture and seamless integration with the HP500 Multi-Cylinder Hydraulic Cone Crusher’s multi-cylinder hydraulic system further bolster durability. The hydraulic system acts as a safeguard, absorbing shock loads and preventing overloads from transferring excessive force to the main frame. This synergy between design and technology mitigates structural wear, extending the main frame’s lifespan.

Precision Manufacturing

State-of-the-art manufacturing techniques, including automated welding and CNC machining, ensure dimensional accuracy and consistency. Non-destructive testing (NDT) methods, such as ultrasonic and radiographic inspections, detect microscopic flaws during production, guaranteeing defect-free components. These processes eliminate weak points that could otherwise propagate cracks over time.

Protective Features and Maintenance

The main frame is shielded by replaceable wear liners, which absorb abrasion from processed materials, preserving the core structure. Additionally, anti-corrosion coatings, such as epoxy layers, protect against environmental degradation in humid or chemically aggressive settings. The design of the main frame also prioritizes accessibility, allowing worn liners or seals to be replaced without dismantling the main frame, thereby reducing downtime and mechanical strain during maintenance.

Proven Longevity in Harsh Environments

In demanding sectors like mining, the HP500 Multi-Cylinder Hydraulic Cone Crusher’s main frame has demonstrated resilience across decades of continuous operation. Its ability to withstand thermal fluctuations, abrasive particulates, and cyclic loading underscores its role as a long-term investment.

In conclusion, the HP500 Multi-Cylinder Hydraulic Cone Crusher’s main frame exemplifies engineering excellence. Through premium materials, intelligent design, meticulous manufacturing, and proactive protection, it achieves unparalleled durability, reliably serving industries for 10 to 20 years. This longevity not only reduces replacement costs but also underscores HP500’s status as a sustainable solution in heavy machinery.

Carrying forward the spirits of fine workmanship for manufacturing, research, development and innovation

------Dedicating to solutions to the mineral crushing and screening.

we are Shanghai Zhuyan Heavy Industry Technology Co., Ltd

email: shanghaizhuyan@gmail.com

facebook: https://www.facebook.com/shanghaizhuyan/